Excellence

in all

its forms

6H55

Development

From concept to creation

We turn plans – sometimes based on mere sketches or concepts – into premium finished products. Whether you are looking to produce a unique piece or a standard collection, we are here to guide you from start to finish. After approving the study, we compile a complete technical file before starting production.

9H30

Choice of materials

Our materials expertise

Our team of technicians has a wealth of experience in working with a range of materials. Do not hesitate to contact us to discuss your plans, whatever material you wish to use. Here is a non-exhaustive list of materials:

- Gold

- Platinium

- Palladium

- Stell

- Titanium

- Brass

- Composites

10h28

Production

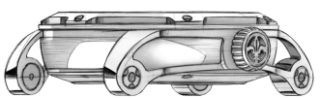

Made to last

Our teams join forces to build on our expertise and maintain an unparalleled level of quality. Our workshop is equipped with CNC milling and turning centres, allowing us to work with a variety of materials, including gold, titanium, steel, platinum, palladium and composites. Our components are made by stamping or are machined directly from the raw material.

Distinguished by brazing. Brazing is an essential step that allows us to offer technical parts while maintaining their aesthetic appeal.

11h49

Finishing

100% finished products

During the finishing stages, all our manufactured components are meticulously treated. Our parts are painstakingly prepared using CNC machines and cutting-edge robots before benefiting from the experience and expertise of our polishers, to give them both the shine and character they deserve.

14h31

Assembly

Exceptional assembly

Every part that we create is unique and assembled with the utmost precision to meet the high standards of fine watchmaking. Our employees exercise extreme care when assembling components, checking water-resistance, performing quality control and packaging our parts.

15h50

Quality control

Meticulous inspection

Technical inspection. Checks are carried out systematically at various stages in the process to maintain consistently high quality standards. These checks may be carried out according to specific standards or each client’s own criteria. We regularly update the measuring instruments used by our quality control inspectors to meet the most stringent standards.

Visual inspection. We pay particular attention to aesthetics from the polishing stage onwards. Inspection allows us to harmonise appearance with technical criteria, ensuring the parts are of optimal quality.